Home » 5S Method

5S method

The 5S method is the model for workplace organization. This clear step-by-step plan for a tidy work environment increases productivity and efficiency on the shop floor, contributes to greater safety and less waste through overview, structure, peace and quiet and good agreements according to the 5S model.

This is done through the application of the 5 S's:

SORT

SHINE

SET IN ORDER

STANDARDIZE

SUSTAIN

5S Company specializes in the application and implementation of 5S. Discover how the 5S system contributes to better and safer work, increased profitability and higher employee satisfaction.

- Increase productivity

- Reduce waste

- A safe working environment

- Working more efficiently and enjoyably

- Attract professionals

- More employee happiness

- Clear processes

- Increase profitability

- Professional appearance towards customers

- Pride in the work environment

5S can be applied to any workplace, within any industry. Find out how 5S Company helps you work more safely, efficiently and profitably. A successful 5S implementation in three phases.

The initial introduction and analysis of the shop floor. During the Gemba Walk, processes and waste are accurately identified for effective rollout of the 5S method.

Assess the 5S level of the shop floor with a 5S audit and verify that 5S has been effectively applied within the organization. Or request a 5S audit to determine the 5S level on your workplace.

What is the 5S method? This is how you work better!

The 5S method is a Lean methodology that creates a clear standard on the shop floor that makes deviations immediately visible and prevents waste. On the basis of a clear step-by-step plan 5S Lean work of a tidy workplace and eliminating waste in the workplace. The 5S model has its origins in Japan. The 5 S's stand for Seriri (separate), Seiton (arrange), Seiso (clean), Seiketsu (standardize) and Shitsuke (Stimulate). 5S for workplace organization is applicable in any industry and for any type of business. Work more safely, enjoyably, productively and professionally? With the implementation of the 5S system within your organization create a safe, clean, well-organized and efficient work environment.

The meaning of the 5S model

1. SORT

1. SORT

2. SHINE

2. SHINE

3. SET IN ORDER

3. SET IN ORDER

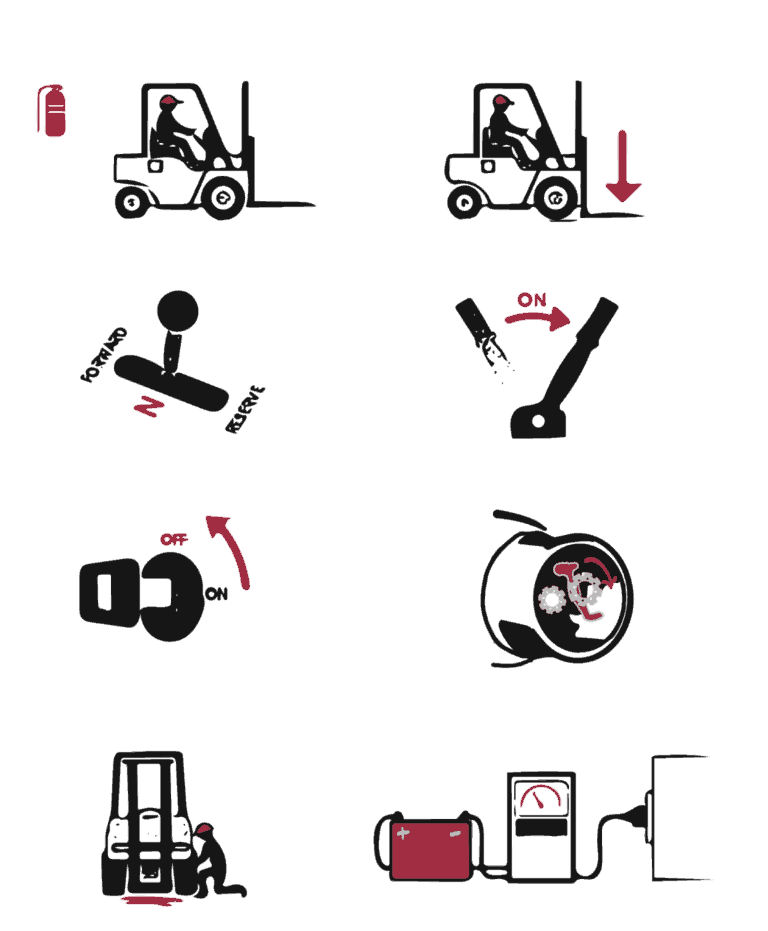

4. STANDARDIZE

4. STANDARDIZE

5S WORKPLACE ORGANIZATION

A 5S organized workplace according to the 5S method is a safe, efficient and pleasant workplace. This work environment automatically helps prevent waste, such as waiting or searching for materials, tools or information. The 5S method also prevents unsafe situations and therefore accidents on the shop floor. In addition to the production benefits of 5S, it makes 5S workplace organization the work environment representative of customers. The value of the product produced is reflected in the production environment.

5S: A LEAN METHOD

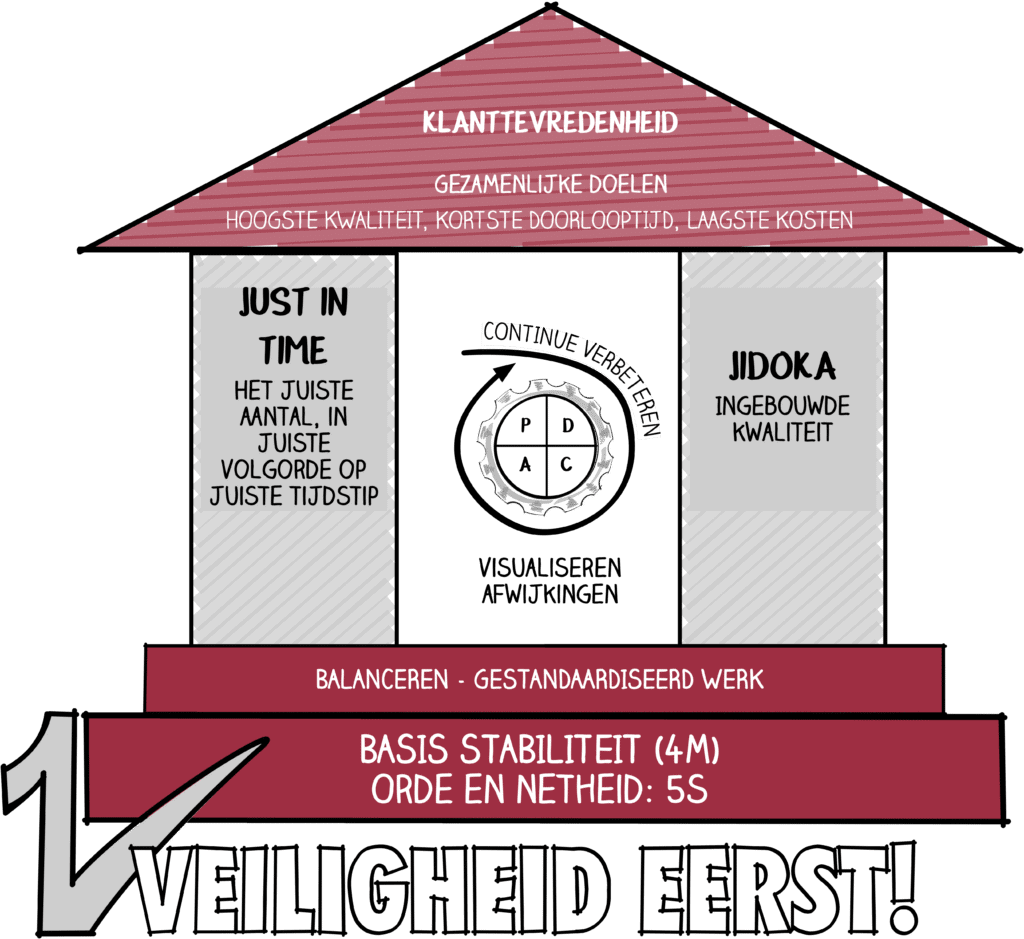

Lean is a methodology that makes every effort to create value for the customer. 5S Lean is a method applied to create basic stability in the workplace. This basic stability is needed to further improve and add more value to the workplace. For your organization and for your customers or users. Stability within the 5S method consists of:

- Everything has a fixed place

- Everything is clean

- Instructions for use are visualized

- The standard is set

- No unsafe situations

- Flow on the workfloor

Are you interested in the possibilities and benefits of 5S for your workfloor? Request a Gemba walk.

EMBRACING THE 5S SYSTEM

A properly utilized 5S Implementation in line with the 5S method establishes a 5S system that’s not only present on the workfloor, but also is in the DNA of employees. To maintain 5S, the involvement of all employees and management is very important. Companies where 5S Company regularly supported already have or had a 5S system in place on the workfloor, but failed to adequately involve employees in the 5S method and approach. Optimizing the 5S system can be realized by:

- Points on the agenda during the day start

- Suggestions for improvement of the system

- 5S semi-digital KPI board

- 5S training

- 5S digital checklist

Would you like more information about the possibilities for applying the 5S model within your company? Or do you have questions about implementing 5S? Dennis is happy to tell you more about the benefits of the 5S method for your business. Contact us or request an immediate no-obligation quote for a 5S implementation.

Permanently improving quality and productivity in the workplace requires teamwork. The 5S training aims to guide employees in professionalizing the workplace with 5S.

Get more insight and control over the results of your 5S deployment with the 5S App. The application supports you in securing 5S on the shop floor and easily conducting 5S audits.

There are various 5S services within 5S Company to make 5S a success within your organization. Discover the benefits of the various 5S services.